The ZJD series crawler reverse circulation full hydraulic drilling rig is mainly used for the construction of pile foundations with medium and large diameters, large depths and complex formations, especially for sand, pebbles and rock formations. This series of drilling rigs have a maximum drilling diameter of 4m and a deepest depth of 150m. They can be constructed on rock layers with a hardness of less than 100MPa. They are widely used for piles such as land construction, water well drilling, port piers, rivers, rivers, lakes, and bridges in the sea. Foundation construction.

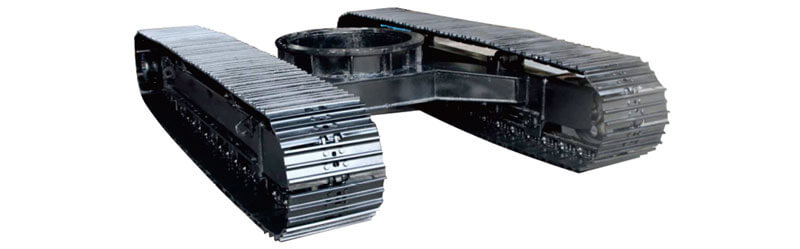

It adopts full hydraulic stepless variable speed, constant pressure and constant speed drilling, equipped with large diameter, low head, large displacement sand pump circulating mud, drilling rig drilling and mud pump operation are all driven by hydraulic motors, which can be automatically adjusted according to construction needs For drilling speed and circulating mud flow, vacuum exhaust is more efficient than liquid filled exhaust. It is equipped with a self-propelled crawler chassis to overturn the traditional use. The movement is more convenient and the operation is more flexible. The reverse circulation slag discharge system of pump suction or air lift is adopted, and the drilling efficiency is high, the hole quality is good, the power consumption is low, the bit life is long, and the use cost is low. This series of drilling rigs have the advantages of high construction efficiency, good site mobility, safe and simple operation and maintenance, and high comprehensive cost performance.

Fully hydraulic drive, high torque, high lifting force configuration, strong working capacity, stable and reliable transmission performance. Adopting Brevini and other international brand power head reducers and Rexroth technology motors to achieve stepless speed regulation without stopping during drilling. The speed and torque of the power head can be automatically adjusted according to different formations to achieve the best working condition. In any environment, it can play excellent work efficiency and excellent performance.

Large-bore cylinders are used to lift the power head and drilling tools, with simple structure, large lifting force, stable and reliable performance, safe use and convenient maintenance. It can also realize the decompression of the cylinder or proper pressurization of drilling, which greatly improves the verticality of the drilling and the speed of the footage.

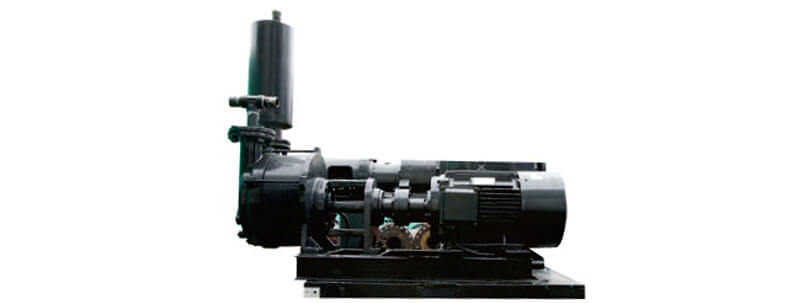

The hydraulic pump station adopts an integral box structure, which can be hoisted and disassembled as a whole to facilitate pump station maintenance. The pump station has a fully enclosed cover door and cover plate, which can effectively protect electrical and hydraulic components. The electrical control has overload, overcurrent, and overvoltage protection functions, which are safe and reliable.

The chassis of the drilling rig adopts a self-propelled crawler chassis with low ground pressure, strong site maneuverability and convenient movement, which can meet the needs of drilling rigs in difficult sites and complex working conditions.

The PLC text monitor can display the main operating parameters of the system and the cause of the failure, and has an audio alarm function. The console of the operating room adopts a stainless steel panel, and the layout of the control handle is reasonable and easy to operate. The drilling rig speed, pressure and other parameters can be set and adjusted on the operating table. The maintenance cost is low, the environment is comfortable, and air conditioning equipment can be installed.

Automatic drilling function:

The drilling rig has an automatic drilling control system, which can set different axial pressures according to the formation conditions and automatically keep the axial pressure constant, which reduces the requirements for operators and improves the efficiency of the drilling rig.

Equipped with large-diameter, low-lift, large-displacement sand pump circulating mud, good pebble passability, strong slag discharge capacity, and variable hydraulic pump drive, which can realize the stepless speed regulation of the sand pump and high efficiency and energy saving.

The drilling rig is equipped with an auxiliary mechanical boom. When disassembling the drill rod, the boom can be used with the drill rod hoist to have the functions of clamping, centering the drill rod and positioning, which is more convenient and labor-saving for lifting and disassembling the drill rod, reducing labor intensity .

It adopts a large displacement water circulation vacuum pump, which is easy to use and maintain, and has high vacuum and exhaust efficiency.

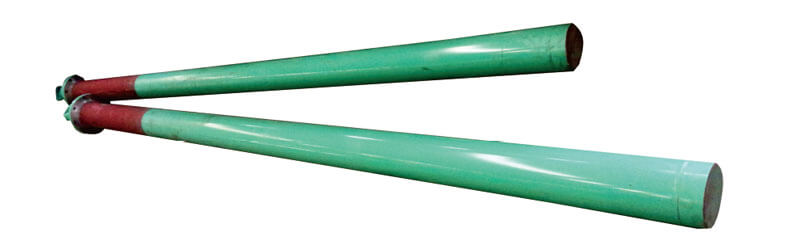

Large diameter thick-wall threaded joint drill pipe adopts special heat treatment and automatic submerged arc welding process, high strength, long life, convenient and quick disassembly of threaded connection, saving time and effort, optional additional weight for pressure at the bottom of the hole to ensure the verticality of the hole , Improve drilling efficiency and quality.

Browse all major components

Browse all major components| Product number | Unit | ZJD2000/100 | ZJD3000/210 |

| Maximum drilling diameter | (Meter) | 2.5(mud)/2(rock) | 4(mud)/3(rock) |

| Maximum drilling depth | (Meter) | 120 | 130 |

| Maximum lifting force | (Ton) | 70 | 110 |

| Working height | (Meter) | 8 | 8.5 |

| Rock hardness | (MPa) | 100 | 100 |

| Drill pipe lifting hoist lifting force | (Ton) | 1 | 2 |

| Power head speed and torque | Rpm | 4 | 4 |

| (Ton·m) | 10 | 21 | |

| (Rpm) | 6 | 19 | |

| (Ton·m) | 8 | 4 | |

| (Rpm) | 17 | / | |

| (Ton·m) | 2.1 | / | |

| Drill rod specifications | (mm) | Ф325×20×2500 | Ф351×20×2500 |

| Reverse circulation gravel pump caliber | (Inch) | 12 | 15 |

| Counterweight (optional) | Ton | 12 | 25 |

| Total power | (kW) | 152(75+55+22) | 187.5 |

| Overall size | (Meter) | 9.2×3×6.5 (Working status) | 10×3×7 (Working status) |

| 9.2×3×3.1(Transportation status) | 10×3×3.1(Transportation status) | ||

| Stand-alone weight | (Ton) | 29 | 41 |

| Slagging method | Pump suction reverse circulation or gas lift reverse circulation | Pump suction reverse circulation or gas lift reverse circulation | Pump suction reverse circulation or gas lift reverse circulation |

| Drilling system | Constant pressure drilling | Constant pressure drilling | Constant pressure drilling |